Rear Suspension

Interestingly, the front and rear suspension were designed in different ways. I wanted to run the widest possible streetable, treaded (pronounced dee-oh-tee ... Not!) rear tires of the proper height that I could find. I did not want fender flares. These two goals dictated the design of the rear suspension (actually the whole back of the car). Since I obviously don’t want such large wheels and tires in the front, my primary goal in the front is to have decent suspension geometry - a pretty lofty goal, considering the ride height.

The first step in the Jaguar rear suspension conversion was to find a used rear suspension from a Jaguar XKE. I wanted a relatively short rear gear ratio, which was not easy to find. The next step was to disassemble the rear suspension completely so that it could be rebuilt and narrowed.

Shortened, ultra heavy-duty rear drive shafts

Radically shortened,

gloss black powder coated control arms

with nylon bushings

Rebuilding the hubs. All roller bearings and metal

bushings were replaced with nylon bushings

Determining the correct height for the rear suspension.

This has a major effect on the suspension geometry.

Making the rear crossmember. Note the cardboard template

at the left, showing the rear tire size and position.

Same thing, viewed from the front.

Rear pinion mounts, connected at bottom to the outer ends of the front tie bar

Rear control arm mounting brackets

Rear anti-roll bar components

Gloss black powder coated anti-roll bar end links

Chrome moly tubing and aluminum rod ends and jam nuts

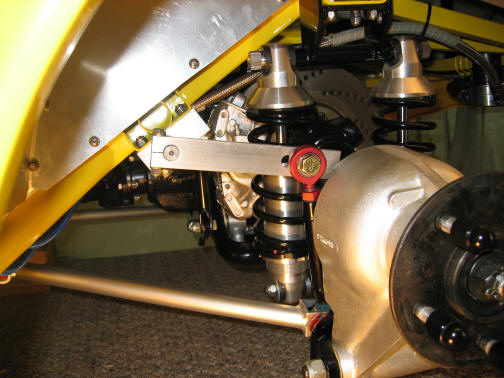

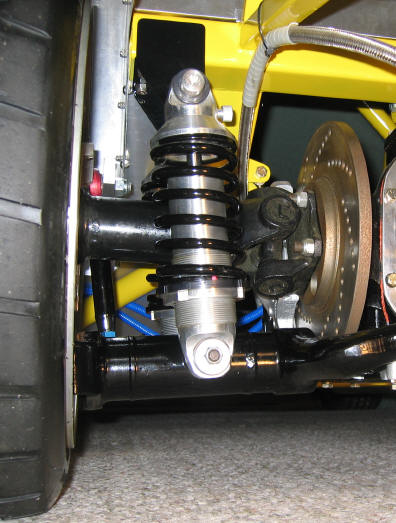

Adjustable aluminum coil-over shocks

One of many test fittings of the rear suspension

The rear anti-roll bar utilizes a straight bar with aluminum arms. This setup is ultra-light weight: the bar with the arms weighs less than four pounds! The long vertical links (chrome-moly tubing with aluminum rod ends) minimize geometry change during suspension travel. Each arm has three holes for adjustable stiffness.

Radius rods

Radius rod bracket

The rear radius rods are made from one-inch OD .095-inch wall mild steel DOM tubing. They utilize a double shear mounted aluminum rod end on the chassis end and a hand made double shear clevis on the outer end. The radius rod inner mounting points are located precisely in line with the control arm inner mounting points.

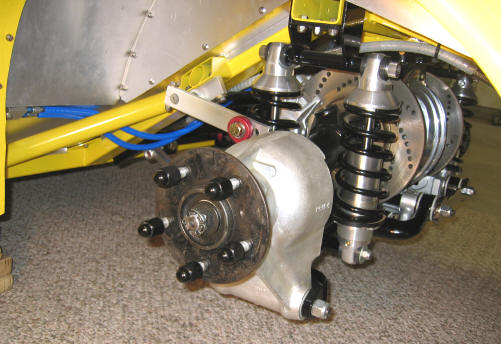

Completed rear suspension, at full droop

The size of the rear tire makes the suspension

and brakes look tiny!

The ride height as shown can be lowered about another two inches, or raised several inches, with the coil-over adjusters so there is plenty of adjustability there. With four soft springs and four adjustable shocks, the rear suspension is very compliant. Camber change during suspension travel is minimal, which helps keep the wide tires in contact with the road.