Roll Cage

The roll cage design was based on two starting points: the proper position for the main hoop (there is only one proper position) and the rear suspension supports. The entire cage is designed to be as strong as possible while still being reasonably light. While I tried to minimize the amount of tubing used I did want it to be safe. I spent a lot of time with the computer, drawings, and mockups before I finalized the design. There are about eight different round tubing sizes and wall thicknesses plus two sizes of rectangular and three sizes of square section tubing. A lot of the tubing is .065" wall which is about one pound per foot in 1-1/2-inch outside diameter round tubing.

Tools for making roll cage tubes: wood clamps, masking tape,

vice grips, paper sleeves, pen, pencil, and patience.

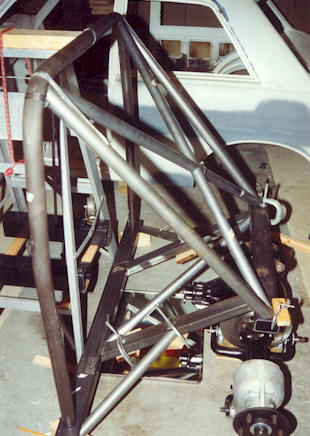

Making braces within the main hoop. This was a

little bit of overkill, so I left out one of the diagonals.

Fitting the roof "halo" and windshield post bars.

Mocking up inside the car...

|

|

|

|

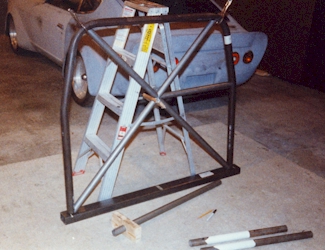

... and outside the car. |

|

As you can see, all tubing joints were carefully shaped

for a perfect fit.

No gaps in tubing fitment means strong, lightweight, good-looking welds.

Five 510s wishing they could have roll cages like this one!

Fitting door bars

String is used to align 2-piece minor bar, which is

slightly smaller in outside diameter than 1-piece major bar

The main hoop with its diagonal brace, rear suspension support with its diagonal brace, top hoop with its diagonal brace, windshield post bars, door bars, and dash bar were all assembled and welded separately before installation in the chassis, so the welds are complete where they are inaccessible if welded in place. The entire cage assembly was also treated with zinc chromate primer. These pictures were taken just before the roll cage was finally welded inside the body. As you can see, this is very close to a tube frame, but much lighter weight.

Complete assembly blocked up for final welding.

Installing front strut tower braces

Bracing inside trunk

Included are diff mounts, rear spring mounts, pinion mounts, two main hoop diagonals, a roof diagonal, X-door bars, provisions for shoulder harness, dash mounts, adjustable pedal bracket mount, steering column mount, fuel cell mounts, battery mount, and a battery ground strap tab. In this picture you can also see the rear wheel tubs and some of the interior aluminum panels.

For

maximum rigidity, there are gussets at key tubing joints within the roll cage. The body is

reinforced at the main attachment points of the roll cage, and there are about twenty

extra supports welded between the roll cage and the chassis! In addition to the brace

shown here between the main hoop and the body, the roll cage is attached along the roof

line, on the door posts, under the dash, and so forth. These connections

make the entire car feel extremely rigid while it is being driven. There

is a very noticeable difference in driving a 510 with a very rigid

chassis like this one and a 510 with a modified suspension but a stock

chassis. Just bolting in a roll cage does not come anywhere close to

accomplishing the same thing. The handling and steering

are very

predictable! This is how I got the most from the advanced

suspension, steering, and brakes

in this car.

For

maximum rigidity, there are gussets at key tubing joints within the roll cage. The body is

reinforced at the main attachment points of the roll cage, and there are about twenty

extra supports welded between the roll cage and the chassis! In addition to the brace

shown here between the main hoop and the body, the roll cage is attached along the roof

line, on the door posts, under the dash, and so forth. These connections

make the entire car feel extremely rigid while it is being driven. There

is a very noticeable difference in driving a 510 with a very rigid

chassis like this one and a 510 with a modified suspension but a stock

chassis. Just bolting in a roll cage does not come anywhere close to

accomplishing the same thing. The handling and steering

are very

predictable! This is how I got the most from the advanced

suspension, steering, and brakes

in this car.

The roll cage is attached to the body in many places.