Engine

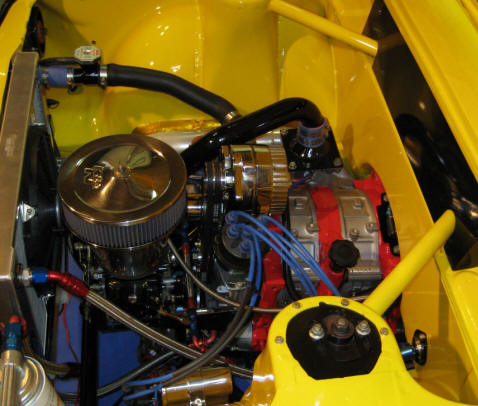

A turbocharged 13B Mazda rotary engine was one of the original and unquestioned aspects of this car's design. I had completed several other 510s with various engines and I had been planning on building a turbo rotary when I obtained this car.

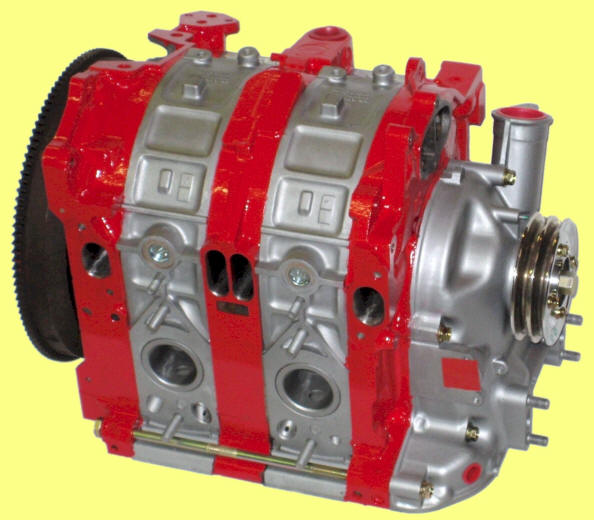

The 13B engine was ported, blueprinted, and rebuilt in June 2007 by Cam Worth of Pettit

Racing

The rotary engine conversion wasn't as straightforward as usual because this engine is lower down and further back than normal. The engine mounts solidly directly to the front crossmember. I had to make my own oil pan and pickup. I had to raise and enlarge the transmission and driveshaft tunnels and modify the firewall to make the engine fit.

Driveshaft

Custom made, gloss black powder coated oil pan with magnetic drain plug

Front engine mount bolts directly to crossmember

3-inch turbine outlet pipe

Exhaust tunnel, driveshaft tunnel, and muffler enclosure.

The aluminum muffler cover was later gloss-black powder coated.

Ron Davis Racing crossflow radiator with SPAL electric fan and built-in oil cooler

Installed radiator

The turbo system is designed to put the turbo in a position where everything is accessible and heat is less of a problem. It's a RotoMaster T04B turbo with a very large turbine wheel and housing, as well as a large compressor, sized to run about one bar of boost on the 13B rotary with minimal back pressure. The ceramic coated exhaust manifold is hand made from 1/8-inch wall steel tubing.

The exhaust system is 3-inch ceramic coated tubing all the way. It is carefully fashioned from mandrel-bent tubing to avoid any tight or sharp bends. The RotoMaster wastegate connects directly into the turbine outlet pipe. The raised area under the passenger seat is where the 3-inch Flowmaster muffler lives. The bottom of the muffler is no lower than the frame rails. On the outlet side of the muffler, I made a tail pipe that exits just ahead of the passenger side rear wheel. It has a short but wide outlet with a built-in, adjustable, Flowmaster-style baffle for a little bit of extra noise reduction. I made this tail pipe very easy to remove so that it can be traded with a special temporary tail pipe I made that can be connected to a metal dryer duct. This is for piping the exhaust outdoors while running the car in the garage.

I had the exhaust pieces (manifold, turbine, and turbine outlet pipe, and tail pipe) ceramic coated and polished. The above picture shows the assembled turbocharger with ceramic coated turbine housing and powder coated compressor housing, ceramic coated turbine outlet pipe, ceramic coated exhaust manifold, and ceramic coated exhaust tip.

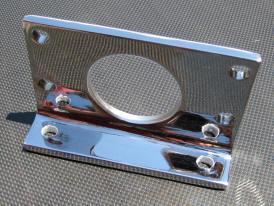

The lubrication system features a gloss black powder coated custom steel oil pan with magnetic drain plug. Dual external oil filters mounted upright for easy oil changes without spillage. FL-1A oil filters. Oil cooler incorporated into custom Ron Davis custom aluminum crossflow radiator. All Aeroquip braided stainless oil lines with anodized aluminum fittings. Gloss black powder coated aluminum oil filter bypass block on engine. Oil temperature gauge on dash with sender in oil filter adapter housing.

The fuel system features an 8-gallon FuelSafe fuel cell which is clear, eliminating the need for a gas gauge (sort of). The electric fuel pump delivers adequate fuel flow and pressure but is small, light, quiet, and draws only a few amps. A billet aluminum filter is included. Aeroquip line is used throughout.

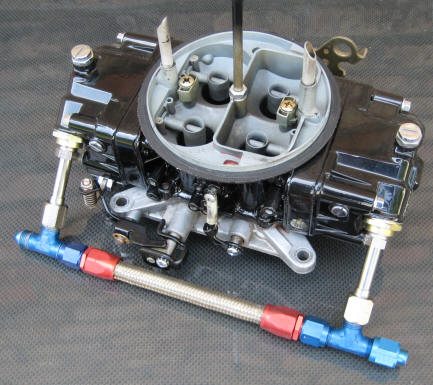

I decided to switch to a different carburetor because the one that I had initially selected, while good for power, was too big for good low-end, non-boost conditions throttle response. I decided on a 390-CFM, 4-barrel Holley double pumper. This is not an easy puppy to find! It's a race carb. I made a few modifications, had the fuel bowls, metering blocks, main body, and various smaller pieces powder coated gloss black, rebuilt it, made a few modifications, and assembled it with all new chrome hardware, high-performance floats, and anti-pullover discharge nozzles.

Because the carb is so low in the engine compartment, I was able to fit a very tall stainless steel velocity stack style K&N air cleaner housing with a K&N foam air filter.