Twin Turbo V6 510

Part 1: Overview

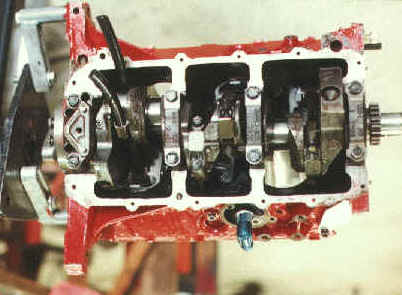

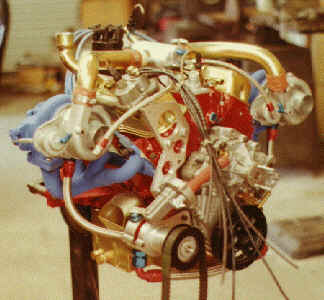

Engine: 60-degree Chevy V6, balanced, blueprinted, ported by Ruggles Racing, polished crank, O-ringed heads, ForgedTrue custom forged low-compression pistons with full floating pins, factory high-output cam, valves, Crane aluminum roller rockers, chrome-moly pushrods.

Turbo setup: Custom-made ceramic coated steel exhaust manifolds, twin RotoMaster T3 turbochargers with built-in wastegates, Cartech recirculating valve, twin intercoolers with custom carbon fiber ducts, K&N air cleaners.

Fuel and ignition systems: EFI, tuned port injection, Electromotive TEC-II fuel injection and crank-triggered direct ignition computer with Blend PROM, TPI intake manifold, Porsche Turbo throttle body, Bosch fuel pump, Aeroquip fuel lines, GM fuel rail, Accel pressure regulator, Siemens injectors, mechanical water injection, Taylor performance plug sires, Bosch platinum spark plugs. No distributor is needed with the TEC!

Exhaust system: Two 3" turbine outlet pipes, joining into one 3" pipe before going through rear subframe. 3-inch two-chamber Flowmaster muffler. Separate wastegate pipes join into exhaust pipes about 2 feet downstream of turbo. Ceramic coated. Ground clearance is excellent!

Lubrication and cooling system: Oversize oil pan with scraper screen,

baffles, 3 one-way trap doors, and built-in oil pickup. Peterson racing external oil pump

with 1" toothed belt drive, large Earl’s oil cooler (mounted behind grille),

remote mount oil filter (FL-1A), custom Corvette aluminum crossflow radiator, Aeroquip -12

and -10 stainless oil lines.

Lubrication and cooling system: Oversize oil pan with scraper screen,

baffles, 3 one-way trap doors, and built-in oil pickup. Peterson racing external oil pump

with 1" toothed belt drive, large Earl’s oil cooler (mounted behind grille),

remote mount oil filter (FL-1A), custom Corvette aluminum crossflow radiator, Aeroquip -12

and -10 stainless oil lines.

Drivetrain: Tilton lightened flywheel, Tilton 900KG pressure plate, KC Tool custom carbon fiber clutch disc (hub and marcel springs), trick Tilton transmission-mounted hydraulic clutch (no fork or arm), Tilton clutch master cylinder, Borg-Warner Super T-10 "Rock Crusher" manual transmission, Hurst Competition Plus shifter, R180 3.90 LSD.

Suspension: Carrera coil overs front and rear. Tilton front strut tops and camber plates. Ultra-quick, front-steer Sweet Engineering rack and pinion steering (front steer), 2 turns from lock to lock. Double-shear mounted front control arms, adjustable tubular front sway bar with lightweight, custom-machined arms, and aluminum rod ends, custom made front subframe, solid-mounted rear subframe with 4-inch exhaust hole and adjustable camber and castor.

Brakes: Front: Huge ventilated rotors (13" diameter, 1.5" thick!) and

huge, lightweight AP Can-Am 4-piston calipers. Rear: ventilated rotors (!) with machined

grooves, and Corvette rear aluminum calipers. Mintex road racing front pads (you should

see their size!) and MetalMaster Corvette rear pads. Tilton dual brake master cylinders

and pedal bracket with adjustable bias bar, Girling 5/8" master cylinders with

reservoir extensions, proportioning valve, and line-lock. All Aeroquip -3 brake and clutch

lines. This 510 stops.

Brakes: Front: Huge ventilated rotors (13" diameter, 1.5" thick!) and

huge, lightweight AP Can-Am 4-piston calipers. Rear: ventilated rotors (!) with machined

grooves, and Corvette rear aluminum calipers. Mintex road racing front pads (you should

see their size!) and MetalMaster Corvette rear pads. Tilton dual brake master cylinders

and pedal bracket with adjustable bias bar, Girling 5/8" master cylinders with

reservoir extensions, proportioning valve, and line-lock. All Aeroquip -3 brake and clutch

lines. This 510 stops.

Wheels and Tires: Centerline drag racing type 2-piece riveted, spun aluminum wheels (they’re light) and Yokohama AVS tires (they’re great!). Front: 15 x 7" wheels and 205/50-15 tires. Rear: 15 x 8-1/2" wheels and 225/50-15 tires. 35 PSI front and rear.

Body: 6-point roll cage (connects to rear shock towers!) with diagonal brace, shoulder harness bar, door bars. 1-1/2" tubing. Body and frame rails reinforced in several key places for added rigidity. Extra tubular structure between grill and radiator to protect radiator (and mount oil cooler). brace between rear shock towers above fuel tank. Trunk-mounted battery. Box flares. Concealed gas filler (inside trunk). New, chrome bumpers. Louvered hood. No emblems or rocker panel moldings. Black side window frames. Dual outside mirrors. No air dams or wings (yet).

Interior: Koenig tan leather seats, nice dash with Auto Meter tach and boost gauge, Westach oil pressure/oil temp gauge, dual exhaust temp gauge and amp/volt gauge in custom center panel. Dashboard has carbon fiber top trim pieces. Custom tan leather door panels and rear side panels, carbon fiber kick panels, white headliner, Momo Jackie Stewart steering wheel, steel rear firewall, tinted (no, make that blacked-out) windows, new black carpet. Retractable aftermarket seatbelt/shoulder harnesses.

Part 2: The Story

Although I have had several 510’s, before I got this car I had never before bought one that was modified except in the smallest ways. That changed one summer when I found out that a particular 510 was available for sale. It’s a long story, and I will start from the beginning.

Many years ago, when I was working for Turbo Tom, a very wealthy person here in Atlanta decided to have Tom build him a very fast 510. Impressed with what Tom could do, he decided to let Tom make all of the decisions.

Tom selected a Chevrolet 2.8-liter V6 engine. This engine was chosen because it’s a 60-degree engine (most V6 engines are 90-degree Vees). It is therefore a very compact engine, leaving room for twin turbos! It's not much heavier than the stock 4-cylinder! A 60-degree V6 with 120-degree crank throw angle like this one is mechanically perfectly balanced. The firing order is even 1-2-3-4-5-6! A modified Porsche fuel injection system was also planned. It turned out that the engine was ideal, as it’s real smooth, very responsive, and has proved to be plenty durable.

An engine from a Chevy truck was acquired. The heads were ported by Ruggles Racing, famous for their work with Buick V6’s. The engine was completely re-done to withstand sustained high-RPM, turbocharged operation. A twin-turbo setup utilizing IHI turbochargers and Bosch CIS fuel injection was fabricated.

A very clean 1972 2-door 510 was purchased for the project. It was stripped and thoroughly cleaned up. The suspension and brakes were modified, using Carrera coil-overs and 4-wheel vented disc brakes. A front subframe incorporating a Ford Pinto steering rack was made. After the engine and transmission mounts, oil pan, turbo setup, and other items were designed and built, the car was sent over to Gaaco Race Car Engineering for a trick, street roll cage, some frame reinforcement work, a rear firewall, and enlargement of the rear wheel openings. Then after more work on the engine and fuel injection system, 24 louvers were punched in the hood and the car was sent to the body shop for box flares and Mercedes-Benz light ivory paint. The engine was fully detailed and installed into the freshly painted chassis. Koenig leather seats were installed. A custom headliner and door panels were made. A zillion details were completed, and the car was delivered to the anxious customer.

That summary really just glosses over what was an enormous project! I couldn’t imagine what it must be like to pick up a car like that and drive away in it. The car was a work of art, a mechanical marvel, a rocketship. I saw it as a showpiece of Tom’s talent. Well, I guess this customer didn’t. He apparently saw it as a rocketship and nothing else. He drove the car hard. He would repeatedly find a weak point (how do you find weak points? Overstress the whole system!), bring it back to Tom, and say "Fix this so I can’t break it again"! Good thing the MSD 7AL had a built-in rev limiter or I am sure he would have scattered that engine. Over time, the car went through several upgrades and refinements, increasing its already high heavy-duty factor. When a better intake manifold (from fuel-injected Camaros) became available, it was adapted to the engine. A Sweet Engineering steering rack was substituted for the Pinto unit. Bigger front brakes were installed. When GM offered a high-performance cam for the engine, that was also utilized. The throttle body was changed from draw-through to blow-through with a recirculating valve. Etc., etc., etc.

After a while (a long while, like many years), he parked the car and quit driving it. Considering the other cars he had to choose from, that’s almost understandable. But since he just considered it a toy, he just left it sitting outside. After all, he had never really taken very good care of it anyway. And this is a car that he had invested a boatload of money into!

Several years later, he decided to sell the car, because it was really just in the way. But it had been sitting outside, it had not run for several years, and it looked terrible. When I heard it was for sale, I figured I could never afford it, but since the car was not in very good condition and was not running, and since the owner wasn’t exactly hurting for money, I was able to get the car for an incredibly cheap price -- about what you might pay for a very clean, stock 2-door 510. I had no idea what kind of condition the engine, transmission, or differential were in, but I figured that just the suspension and brakes were worth several times what I paid for the whole car!

With the Bosch CIS injection

After conversion to EFI

The biggest problem was that the fuel injection system was completely gummed up with old gas. By thoroughly cleaning and rebuilding the Bosch CIS fuel injection system, I was able to make the car run, and while it did not run very well, I was happy to know that the engine itself seemed OK. I decided to get rid of the whole fuel injection and ignition system and convert to an Electromotive TEC-II fuel injection/direct ignition system. This completely transformed the car, which immediately ran better than it ever had! But it still needed a lot of work.

The car was so dirty and neglected, I spent days cleaning it inside and out. The tires, brakes and clutch were totally worn out. I removed the engine and transmission, replaced all the seals and gaskets, had everything powder coated (blue) and ceramic coated (silver), and replaced the clutch. A lot of the stock wiring had to be replaced. Lots of items that I considered unneeded were removed from the car ( I love simplicity).

This car also represents my initiation to EFI. I resisted for a long time because I considered EFI to be more complicated, less reliable, and only slightly better than carburetion. What have I learned? That while it is a little more complicated, it is much more reliable and far superior! So good, in fact, that I will now turn my back on Holleys and Mikunis and never look back. "Change is good"

The TEC fires the fuel injectors and the spark plugs (and controls the wastegates) using only a crank position sensor, intake manifold pressure and temperature sensors, and a coolant temperature sensor. No air flow meter or oxygen sensor is used. A throttle position sensor is used only for data logging. I’m using open-loop, sequential injection with one injector pulse per crankshaft revolution per cylinder at this time. It is extremely smooth! The TEC supports data logging and graphic playback of numerous engine, spark, and fuel parameters. You can record hours worth of driving and then review the details later to figure out what is happening. It’s ultra-cool!

A shift light on the dash begins to glow at 1000 RPM before redline and keeps getting brighter until redline is reached. If you continue to rev the engine, the timing is quickly retarded so you feel a big drop in power, making it natural to want to shift. If you still keep revving the engine, the rev limiter cuts off the spark until the engine speed comes down by 50 RPM.

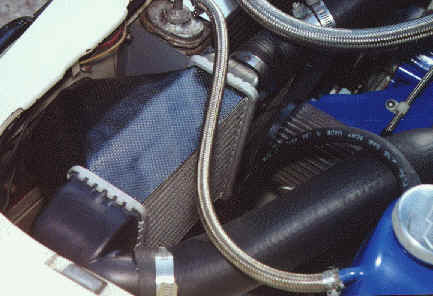

Here you can see the tuned intake runners, the fuel rail, pressure regulator, injectors, the TEC-II, the turbos, the brake master cylinders, the stainless braided top radiator hose, and much more.

In April 1996, I started hearing a shrieking noise under boost. The turbos were worn out and one of them was starting to make contact between the compressor wheel and the housing. I wanted to get these turbos rebuilt but it was going to be very expensive since they were old and not great turbos. I decided to switch to some new, bigger turbos, which Turbonetics custom assembled for me. I had to modify the exhaust manifolds (weld on new flanges) and I went ahead and made 3-inch turbine outlet pipes - the old setup used 2-1/2 inch pipes, and so this greatly increased the flow. This is important for turbochargers. I had the exhaust manifolds, turbine housings, and turbine outlet pipes ceramic coated and polished. Once these new turbos were installed and the fuel injection was re-calibrated to compensate, the car again ran better than ever!

The Turbonetics T3 turbos and 3-inch turbine outlet pipes

By this time I had a "carbon fiber fixation" and was trying to have at least one carbon fiber part on each of my cars. For this car I made carbon fiber kick panels since it didn't have any kick panels at all. Flat carbon fiber panels aren't too much trouble to make.

Black carbon fiber kick panel

For quite some time I had wanted intercoolers for this car. Nothing improves the efficiency of a turbocharged engine like intercooling, and having spend a lot of time analyzing data files that I had logged while driving the car I knew that the intake manifold temperature really shot up under boost, which is a normal physical reaction to the air being compressed. Hotter air is less dense than cooler air, and therefore can support less fuel and so makes less power.

By way of the Internet I found an individual that had upgraded the intercoolers on his 300ZX turbo and still had his original intercoolers in excellent condition. I bought these intercoolers for a great price and installed them on either side of the radiator, directly behind the high beam headlights, which I have removed. I then made some carbon fiber ducts to force the incoming air through the intercoolers, to ensure their efficiency in warmer weather. (This required making a custom mold.) After this installation, I had to recalibrate the fuel injection system to deliver about 12 percent more fuel, so I have improved the efficiency (and therefore power) of the engine by about 12 percent, or roughly 40 horses. I also noticed that turning up the boost beyond 15 psi had a dramatic effect where there used to be little power gain by going over about 15 psi because of the heat the turbos were generating. Now that the intake temperature is not going up under boost, I am not getting that efficiency dropoff. I am considering adding some fans, so the intercoolers will work as well as possible at lower speeds on even the hottest days.

At full throttle in fourth gear, running 20 psi boost, the car went from 3000 RPM to 5000 RPM (approximately 55 to 90 MPH) in about 2 seconds! (It's insane.) The on-board data logger is very useful for this kind of testing. It's also good for delivering bad news, such as the fact that the injectors are now on the small side for the power that the car is making (at 20 PSI and 6000 RPM they are over 90% duty cycle, which is maxed out.) If necessary I can increase the fuel pressure but for now I am keeping the wastegates set at about 16 PSI.

The twin intercooler installation

Other changes: Powder coated the 3 piece grille assembly (gloss black). Replaced the racing harnesses with some aftermarket retractable shoulder/lap belts I found in Street Rodder magazine. Did a lot more detailing of the paint: wet sanding, compounding, buffing, polishing, and touching up. It still looks rough, but it's not as rough as it was! Replaced the old-style, rusty 3-inch Flowmaster muffler with the new style one, which has a better internal design and also is aluminized. Replaced all the exhaust clamps with stainless steel ones. Used the low-ground-clearance type exhaust clamps at the low points.

Chevy High Performance magazine had been discussing this V6 engine so I sent a letter with a description of the engine, fuel injection and turbo setup and a picture of the engine and they printed it on page 7 of the November 1996 issue.

I tried autocrossing the car in September 1997 and had a lot of fun. But I learned a couple of things that will be a big help next time. Like I need more front tire pressure, less front sway bar, more rear sway bar, and more negative front camber. Next time. Fortunately all of these items are adjustable on this 510.

In December 1997 I made some carbon fiber dash top trim pieces using the original ones as molds. These came out nice and it looks very trick but did not really save much weight since the original pieces were pretty light anyway. Mainly I did this because I wanted some carbon fiber that can be easily seen - the other carbon fiber pieces on the car (so far, the inside front kick panels and the intercooler ducts) aren't very visible. I think carbon fiber looks great in bright sunlight!

This is a 510 to remember! It ran perfectly. The steering was fast and tight and felt far better than non-rack-and-pinion 510s. The brakes were super powerful and the car stopped great! It sounded ultra cool, with distinctly different sounds in acceleration mode (turbo scream), deceleration mode (recirc valve whoosh), and cruise mode ("like a swarm of mad bees" according to Rob Fuller). The engine was super smooth, very throttle-responsive, and got boost fast. I sold this car in August, 1999. I miss it.

Speed-Wiz automotive analysis, design, and simulation software